Built in the early sixties, UPM’s Pietarsaari pulp mill goes through an impressive 200 truckloads and three cargo trains worth of wood in a day. The winding courtyard, a throwback to a different era, is different from streamlined modern mills and harbours 10 boiler towers and hundreds of metres of pipelines.

The serpentine of yellow pipes goes through four factory floors, with loudly humming machines signalling different parts of the journey. Each chip of wood that enters the system comes out 15 to 20 hours later as fluffy, popcorn-like pulp.

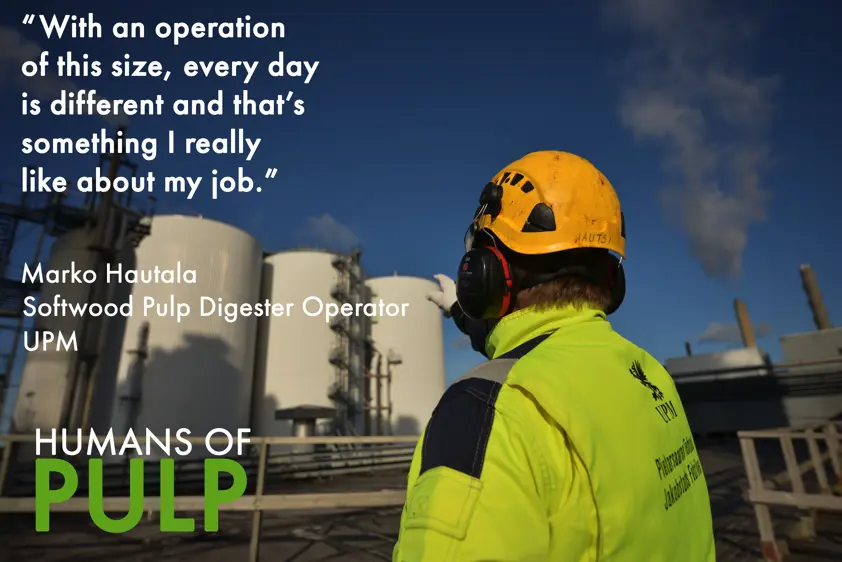

At the base of the towering mountain of wood shavings stands a man who looks awfully small in comparison. But there is nothing small in what he does. “We always have someone circling the premises. It takes a few hours to go through the whole area,” says Marko Hautala, a man who many consider one of the big brothers of the factory. His job is to keep a keen eye on every part of the mill’s processes and ensure the safety of his colleagues.

On the fourth floor stands a room draped in computer screens. This is where Marko spends most of his time. He and his colleagues observe every step of production from here, keeping an eye out for anything that might seem out of place. Their day to day job consists of monitoring the pulp’s journey through the mill using real-life footage and data collected from the factory floors. If there is an issue, they isolate the scene, close the pipelines, call in the appropriate personnel and make sure everything is handled as per protocol.

“We take safety very seriously, 110 percent,” he states. “Safety is something that has grown in importance since I started here.” And he should know. Marko and UPM have spent as much time together as apart: 23 years to be exact. For a whopping 21 years and seven months of that time, he has been the person who makes sure each and every problem is handled as efficiently and safely as possible.

Pulp runs in the family

Even as a kid, Marko was no stranger to the pulp industry. His father is also a UPM stalwart, having started working for the company as far back as 1974. Following in his father’s footsteps, Hautala junior started studying chemical processing and, sure enough, he was soon working at the mill’s power plant. From there, he quickly ascended to his current position.

He says he still remembers the jitters he had when he first started. “These days I’m not nervous about anything except the thunder. That’s really the only thing you can’t do anything about,” he says. “With an operation of this size, every day is different and that’s something I really like about my job.”

Looking after the mill is literally an ‘all day everyday’ job. It runs day and night all year round, aside from a short annual break when maintenance is done. Marko’s work schedule keeps him busy at all hours of the day, but that doesn’t mean he can’t have a life outside the mill. “I’m an avid bowler. I coach the junior bowling team and we have a company team, too,” he says with a smile on his face.

Marko’s two boys also regularly join him for a few frames. “My daughter, on the other hand, is more artistic and enjoys things like baking,” he beams. The proud husband and father of three also has a hobby just for himself: fishing – or, more specifically, fly fishing. “I do around six fishing trips every year. There is something very blissful in listening to the babbling brooks and watching the campfire,” he says.

Though Marko has already earned an enviable track record for himself at UPM, he has his eyes set on the future. “I think we all dream of a new mill,” he says. “It would bring with it more longevity and efficiency, and I would personally love to experience what it’s like working in a new one.”

Text: Julia Ruottinen