Since the turn of the new millennium, there has been a lot of buzz around nanotechnology and the benefits it could bring us. In fact, lab-grown meat, 3D-printed organs and cosmetics not tested on animals already exist thanks to this technology.

3D cell cultures aren’t generally the first things that come to mind when thinking of possible end uses for wood pulp. Yet this is exactly what UPM has developed over the past decade with GrowDex, an animal-free hydrogel extracted from birch wood. The raw birch wood is first processed into wood pulp with the pulp fibres then being used to create the nanofibrillar cellulose (NFC) hydrogel.

A new kind of material

Keeping in mind the EU directive to eliminate the use of animal products where possible in the development of new drugs, as well as in cosmetic testing, Pekka Hurskainen, VP, Strategy and New Business Development at UPM says “We believe there is a demand for this kind of hydrogel which is created from wood-based material.”

“Our competitors’ products are either synthetic or animal based, so our product is very different,” explains Hurskainen. “Our wood is sourced from sustainable and responsibly managed forests, so that’s also been one element that our customers like us for, the fact that we have FSC® and PEFCTM certificates for our raw material.”

While UPM began researching the development of nanocellulose and its applications for the company early on, it wasn’t until much later that nanocellulose’s true potential became clear.

An innovative history

UPM established the Finnish Nanocellulose Centre in Otaniemi, Finland in 2008 along with its research partners, VTT and Aalto University, where they first began studying nanocellulose.

“In the beginning, we thought nanocellulose could be used in some of our paper products, for giving strength to the paper or then as a kind of coating material,” says Hurskainen.

Later that same year, UPM conducted the first cell culture tests in partnership with the University of Helsinki, which was the beginning of the Biomedical applications for GrowDex.

The first scientific article related to GrowDex was published in 2012, and the research continued, culminating in the launch of the GrowDex hydrogel product in 2014.

The case for 3D cell cultures

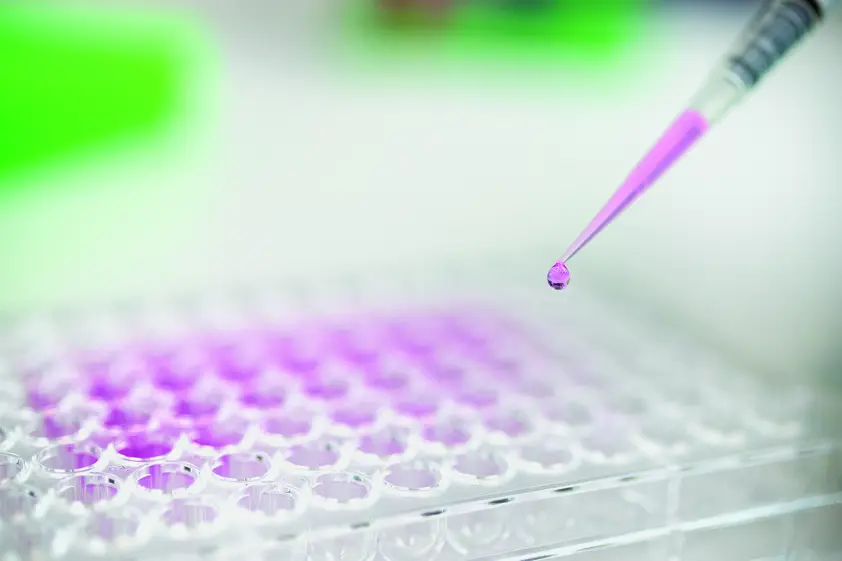

Cell culture, the process of growing cells outside of their natural environment and under controlled laboratory conditions, involve both 2D and 3D techniques.

“3D is becoming more popular as it mimics more a cell’s natural environment than is possible in 2D culture, and it is generally agreed 3D cultures are also more biologically relevant. It is the new way of doing cell culture,” explains Hurskainen. “We evaluated the business case and the market potential for different applications and found 3D cell culture to be the most promising.”

This played a large role in UPM’s decision to focus on the Biomedical market for GrowDex.

“The cell culture market is a big market, something like EUR 12 billion and it is growing quite rapidly. There is also healthy growth in the 3D cell culture areas, it’s currently worth EUR 3 million and its growth rate is something between 20-30%,” adds Hurskainen.

Biomedical applications

GrowDex hydrogel is biocompatible and as such provides an ideal environment to support and study cell growth and behaviour. Cells, spheroids (mini-tumours) and biopsy samples can all be cultured in GrowDex and used to study, for example, drug response for the development of new medicines or in personalised medicine for cancer treatment.

The hydrogel can also be used in 3D printing and, in combination with cells, offers a way to create tissues or structures. Creation of skin models using human cells for testing drugs, chemicals or cosmetics offers an alternative to animal tests which would provide more applicable data. Additionally, combining GrowDex and cells into a scaffold could in the future be used in tissue engineering for the generation of human implants for tissue repair and regeneration.

The future is 3D

3D cell culture has widespread applications, including use in veterinary medicine, but UPM is currently focusing research on humans as they see the great potential for hydrogels for medical innovation.

“Cell culture is used by pharmaceutical companies, by biotech companies, research institutes and hospitals. It is mainly used for cell research, development of different disease models, safety testing, drug discovery and development, regenerative medicine and tissue engineering,” says Hurskainen.

“If we think of the existing applications, the biggest ones are cancer research, drug screening and stem cell and regenerative medicine,” he adds. “But if we think in the longer term, then naturally clinical applications such as wound healing, implants, diagnostics are all potential areas for hydrogels.”

Read more about UPM Biomedicals

Read more about UPM Pulp

Text: Saana Kallioinen