It might sound downright bizarre, but the solutions to our planet’s problems could stem from trees, or rather wood pulp and other material produced from trees. Recent advancements in the field of wood pulp technology have catapulted the industry to the forefront of the sustainable revolution, due to its tremendous potential.

Nanocellulose, the next wonder material?

Advances in the sector are also set to reach further and into other fields. For example, it is hoped that nanocellulose, a gel-like substance refined from wood pulp, will replace harmful metals and plastics in batteries and sensors, as well as smart packaging – where it could be used both as an electrical and protective component.

Far from being a concept that will be realised decades in the future when flying cars and hoverboards finally hit the streets, the arrival of cutting-edge technology such as 3D printers has made its commercial use a reality.

At the start of the year, Japanese company Mui launched its first Internet-connected block of wood, which can control temperature, adjust lighting, open smart doorbells, play music and tell the time via its touchscreen LCD display icons.

The food industry is also set to benefit, with nanocellulose acting as a low-calorie alternative to many carbohydrate-rich additives. Other potential uses include cleaning up oil spillages and creating computer components. Soon, the scope of wood-based materials could be broadened even further to help power cars, aeroplanes and even industries.

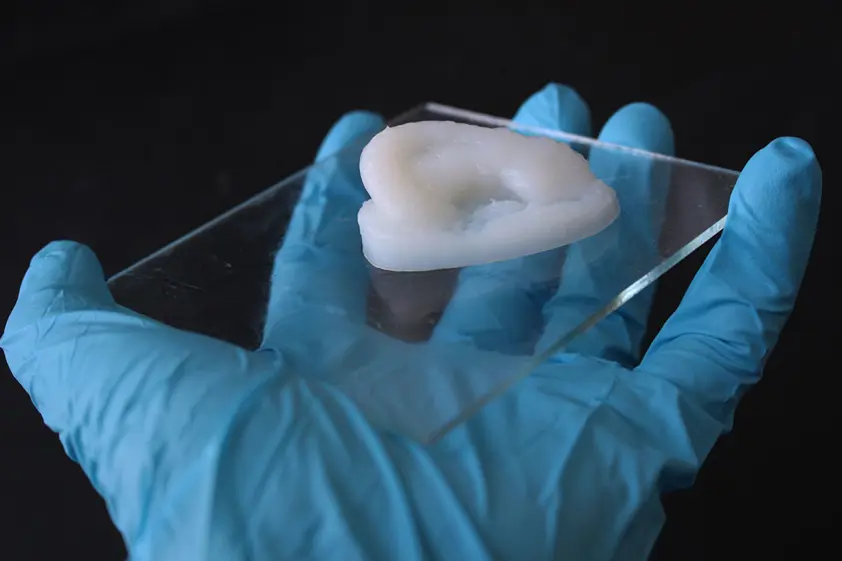

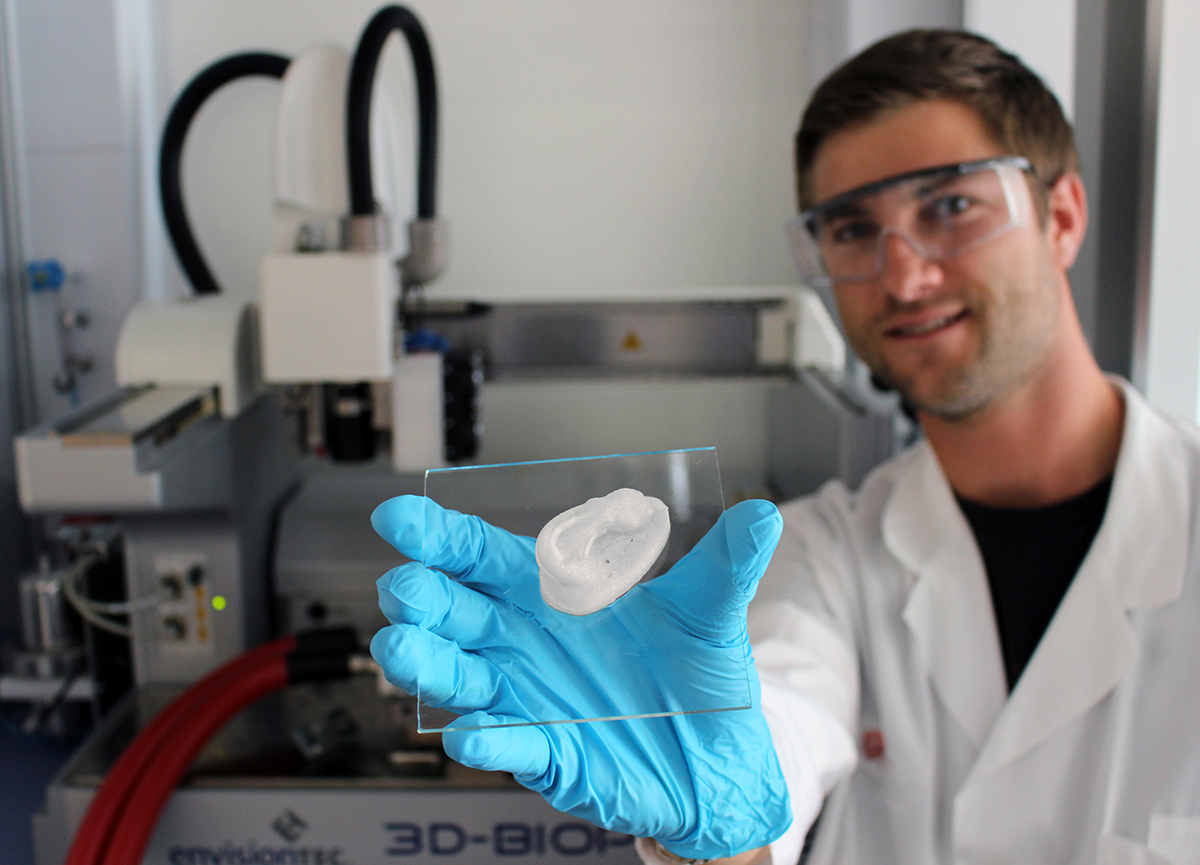

Scientists at the Swiss Federal Laboratories for Materials Science and Technology (EMPA) are using nanocellulose to replace worn out or snapped cartilage in the human body (Image: Empa).

A breakthrough for the medical industry

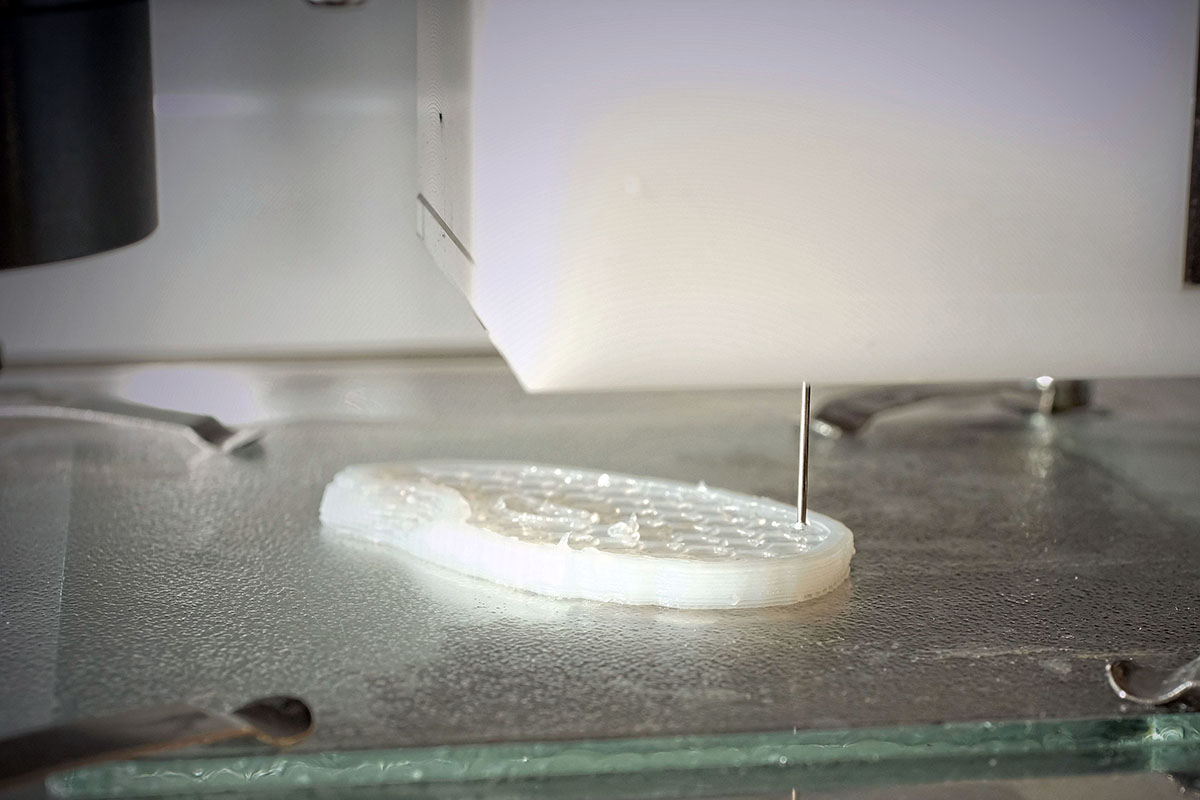

The medical sector is also set to benefit massively from this technology. For instance, scientists at the Swiss Federal Laboratories for Materials Science and Technology (EMPA) are using nanocellulose to replace worn out or snapped cartilage in the human body. One of the interests lies in preparing scaffolds for tissue growth that could be used to replicate a human ear, with more widespread use expected in the near future.

Further, nanocellulose may also be used as aerogels in sanitary products like nappies, tampons and wound dressings, while ingesting the material in tablet form could treat internal disorders.

Dr Gustav Nyström, the Head of Laboratory for Cellulose & Wood Materials at EMPA, is optimistic about the results of this research. “The main driver for this work is the sustainability and biocompatibility of cellulose and therefore nanocellulose can be used to reinforce the hydrogels that form the basis of new tissue regeneration, including cartilage,” he stated.

Green electronics for a sustainable future

Professor Woo Soo Kim from Canada’s Simon Fraser University (SFU) has been establishing 3D printed electronic technologies with nanocellulose’s various elements and its ability to create green electronics. He hopes that such experiments can lead to plastic-free circuit boards being produced by 3D-printers on a mass scale.

Using the bioplotter, the viscous nanocellulose hydrogel can be printed into complex shapes (Image: Empa).

Kim, an academic at SFU’s School of Mechatronic Systems Engineering, said of his latest work: “My research indicates tremendous potential in the sustainable manufacturing of green electronics, such as green electronic applications including green circuit boards, wireless bio-degradable IoT sensors and environment-friendly printable filament. There are a lot of material savings that could be realised with this.”

With these advancements in wood-pulp technology comes a virtually limitless list of possibilities. Kim believes that “green circuit boards will undoubtedly power the most efficient solutions to the global energy and environmental challenges we face as a society. In particular, the abundant resources of wood-derived materials will boost this technology’s application fields.”

Nyström is also convinced that the industry has a great deal to offer, with more innovations on the way. He concluded by saying that “we are optimistic about the future and hope that some of these materials will be able to fill important functions in the future sustainable society.”

Writer: Craig Houston

Photos: the Swiss Federal Laboratories for Materials Science and Technology (EMPA)